- OLYMPUS DIGITAL CAMERA

- OLYMPUS DIGITAL CAMERA

- OLYMPUS DIGITAL CAMERA

- OLYMPUS DIGITAL CAMERA

Project Description

| MEP Contractor | Faisal Electro-Mechanical Co. Ltd. |

| Location | Al Ahsa, KSA |

| End User | Ministry of Higher Education |

| Client | King Faisal University |

| Project Management | University PM |

| Consultant | Zuhair Fayez Partnership (ZFP) |

| Type of Project | District Cooling & Infrastructure |

| Total Value (SAR) | 290.8 Million Saudi Riyal |

| Start Date | Jun, 2010 |

| Finish Date | Jun, 2013 |

| Total Land Area | 500,000 m2 |

| Total Built-up Area |

Work Description

Civil, Mechanical, & Electrical Infrastructure & Utilities Works

Scope of Work

Site Development

-

- Excavation & Backfilling: 263,000 m³ & 220,000 m³

- Concrete Works: 8,000 m³

- Asphalt Works: 52,000 m²

- Curbstone: 10,000 m²

- Chilled Water Piping System: 4,500 m

- Storm Water Piping System: 800 m

- Sewage Water Piping System: 2,200 m

- Potable Water Piping System: 2,200 m

- Raw Water Piping System: 2,800 m

- Well Water Piping System: 500 m for 3 nos. deep well

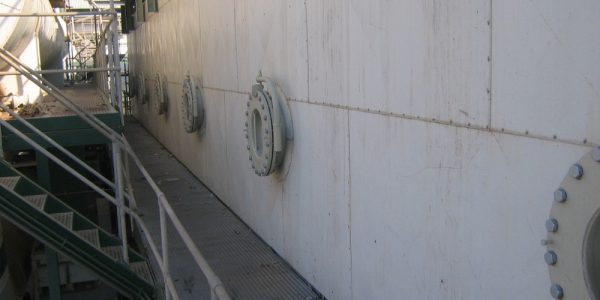

- Reverse Osmosis (RO) Unit: 2 nos. Capacity 750 m³/day

- Break Water Tank: 1 nos. Capacity 500 m³

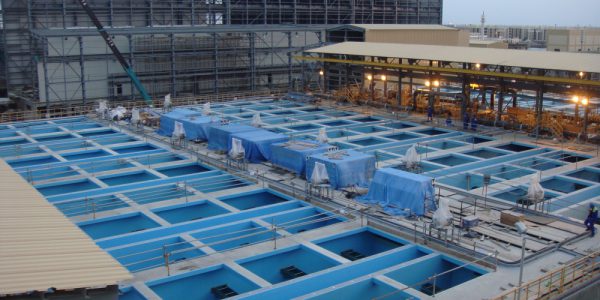

Chiller Plant

-

- Water Cooled Centrifugal Chillers: 6 nos. Capacity 2,151 TR each (TOTAL 12,906 TR)

- Air Cooler Radiators: 44 nos. Capacity 269 TR each (TOTAL 11,836 TR)

- Primary Chilled Pumps: 8 nos. TDH 2.6 bar, Capacity 3,250 GPM

- Condenser Water Pumps: 8 nos. TDH 3.7 bar, Capacity 7,300 GPM

- Secondary Chilled Pumps: 5 nos. TDH 6 bar, Capacity 5,700 GPM

- Boilers: 4 nos. Capacity 7,710 kg/hr

Generator Plant

-

- Generators: 5 nos. Capacity 2500kVA each

- MV Switchgear: 1 no. 13.8 kV, 2500 kVA

Pump Rooms

-

- Raw Water Pump: 4 nos. TDH 9.5 bar, Capacity 161 GPM

- Irrigation Water Pump: 3 nos. TDH 6.5 bar, Capacity 250 GPM

- Fire Pump: 2 nos. TDH 13.5 bar, Capacity 47 GPM