Project Description

| Contractor | Faisal Electro-Mechanical Co. Ltd. |

| Location | King Abdulaziz Int’l Airport (KAIA), Jeddah |

| End User | SAL – Saudi Logistic Services |

| Client | Saudi Tabreed District Cooling Company |

| Project Management | AECOM |

| Consultant | SNC-Lavalin |

| Type of Project | Pipeline |

| Total Value (SAR) | 12.5 Million Saudi Riyal |

| Start Date | Dec, 2022 |

| Finish Date | May, 2023 |

| Total Pipeline Length | 3,500 LM |

| Total Built-up Area |

Work Description

NWC-SWCC Connection Points Bulk Meter Projects

Scope of Work

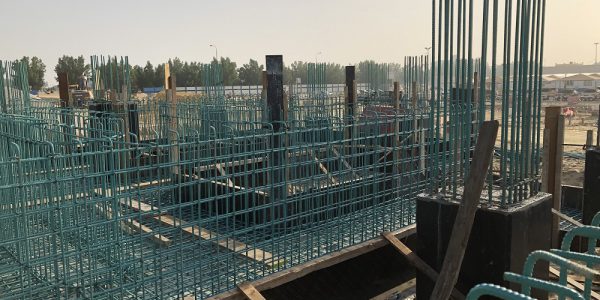

- Construction of Valve Chambers (12 No’s)

- Supply & Installation of Isolation Valves (8 No’s)

- Supply & Installation of Dismantling Joints (6 No’s)

- Supply & Installation of Automatic Air Vents(4 No’s)

- Supply & Installation of Washout Valves (6 No’s)

- Supply & Installation of 24X14inch Hot-Tapping Connection

- Supply & Installation of Pre-Insulated Carbon Steel Pipes (3,415 m)

- Supply & Installation of Leak Detection System

- Flushing, Passivation and Cleaning of the System