Project Description

| Main Contractor | ACWA Power SASAKURA (APS) |

| Sub-Contractor | Faisal Electro-Mechanical Co. Ltd. |

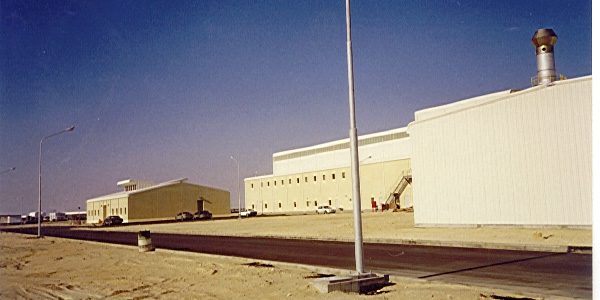

| Location | Shuaiba, KSA |

| End User | Saline Water Conversion Corporation (SWCC) |

| Client | Saline Water Conversion Corporation (SWCC) |

| Project Management | SWCC-PM |

| Consultant | |

| Type of Project | Water & Power |

| Total Value (SAR) | 42 Million Saudi Riyal |

| Start Date | Mar, 2017 |

| Finish Date | Nov, 2018 |

| Total Land Area | |

| Total Built-up Area |

Work Description

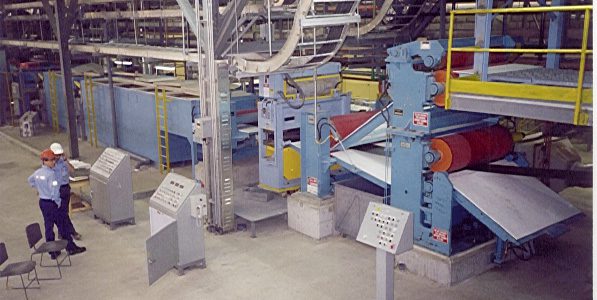

Civil, Electrical, Mechanical & Instrumentation Work

Scope of Work

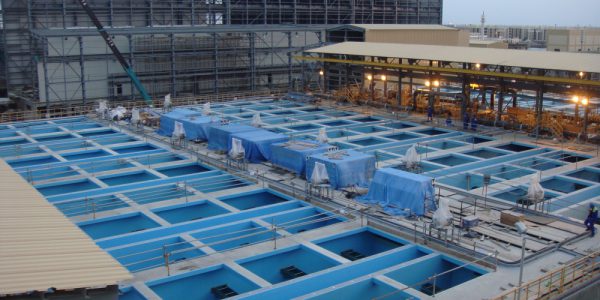

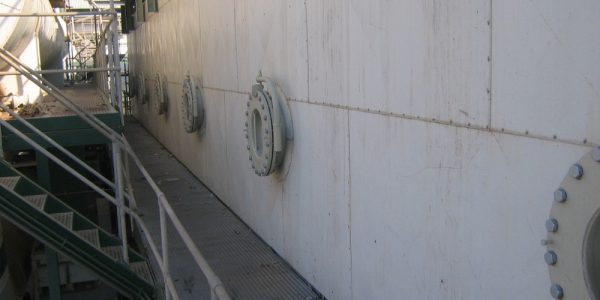

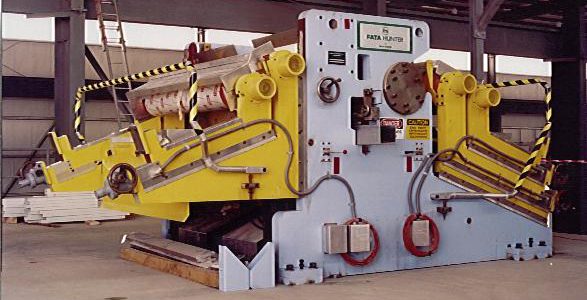

- The complete package / built-up MED Evaporator Unit (91,200 m³ /day).

- Package CVL – 02 Civil Works; earthworks, foundations, road works,

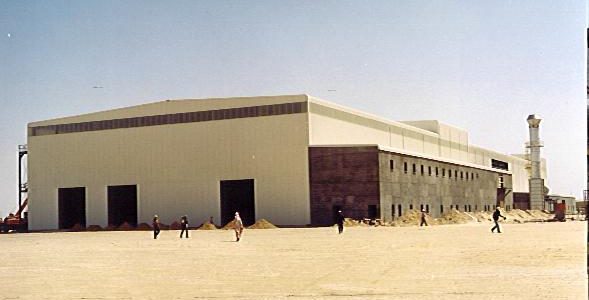

- Construction of Electrical Control & Switchgear Building and Discharge pit etc.

- Package EMP – 01 Electromechanical erection works, with limited supply items such as insulation for piping materials, support materials etc.